Maximizing Power Generation Efficiency: The Strength of Caltex Lubricants for Gas Engines

Natural gas and dual fuel engine markets have been evolving rapidly, with some of its primary growth segments being power generation and gas gathering and compression operations, as well as inland and coastal marine, petrochemical and agriculture. Today, gas and dual fuel engines are being designed to best serve these segments, by ensuring these engines deliver more efficiency, with trends toward steel pistons that have higher-placed piston rings and are exposed to hotter temperatures. Then there are the regulations to reduce emissions driving another trend to reduce oil consumption of the engine, which in turn creates added stress on the oil because the replenishment of fresh oil is reduced. This is where Chevron has stepped in and formulated a full line of Caltex gas and dual fuel engine oils to meet today’s operational challenges across segments. Besides products, Chevron also offers industry expertise to create smart holistic lubrication programs that help operators protect equipment, extend oil drain intervals and ensure optimum uptime. In this blog, we will learn more about the strength of Caltex’s range of products in meeting the requirements of the plant equipment, the solutions and services provided by Caltex that extend beyond products and its role in maximizing power generation efficiency.

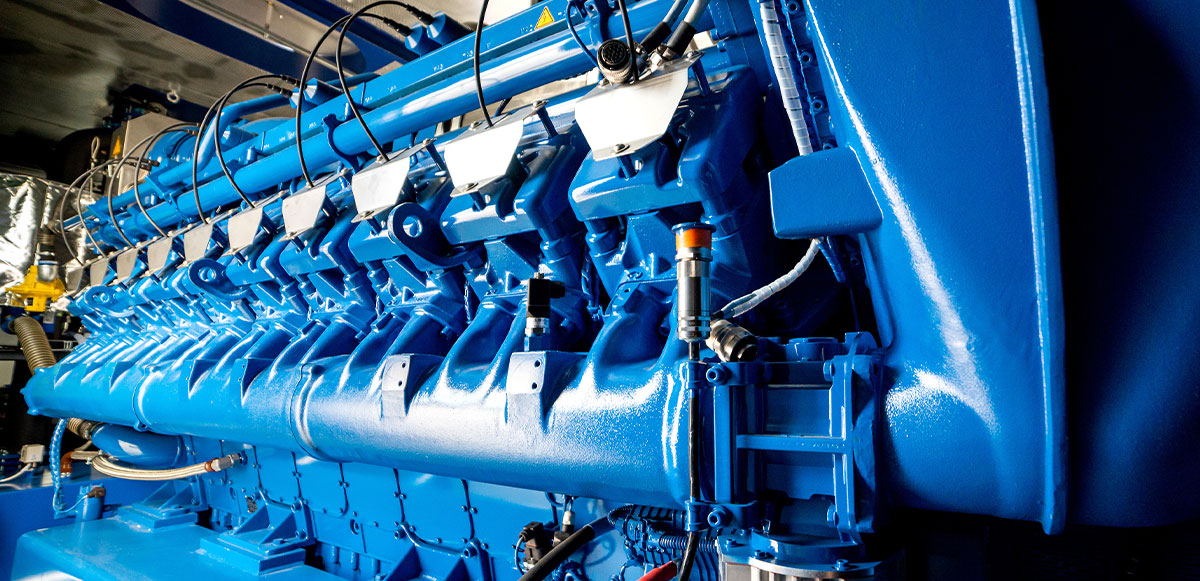

Strength of Caltex lubricants

When you take a look at the plant equipment, you will learn that Caltex range of products can service different parts of the plant. Take, the engine for instance, a range of premium performance engine oils such as HDAX 9300, HDAX 9200, HDAX 7200, HDAX 5200, and HDAX 6500 can promote engine cleanliness, minimizing sludge formation and protecting against filter plugging. There is the cooling system, for which there are antifreeze/coolants such as Delo XLC Antifreeze Concentrate / Premixed, Delo XLI Corrosion Inhibitor Concentrate / Premixed, HDAX ELC Antifreeze/ Coolant 40/60 that can provide minimized maintenance and related costs. The cooling fan and generator can be protected from rust and corrosion by electric motor bearing grease such as SRI Grease 2 and multi-purpose EP grease like Multifak EP 1, 2.

Caltex’s solutions lie beyond its products

Ensuring that the gas engine is in top notch condition is not an easy task. Often, it is bogged down by several issues such as overheating, low gas quality, low TBN & ipH, high oxidation and nitration, high deposits, valve recession or guttering and excessive oil consumption resulting in engine wear, shorter oil drain intervals, higher operating cost, and consequential income loss. Most often, the root causes of these underlying conditions are due to poor coolant maintenance, acidic gas, poor oil quality and incorrect oil type. Caltex has a number of lubricants that can target and solve the many issues faced by gas engines but where Caltex stands out are its services such as Lubewatch services and its team of in-house segment experts for technical support.

What’s Caltex LubeWatch services?

LubeWatch’s 3‐Tiered flexibility drives sales with its range of flexible UOA services designed to meet individual customer needs. Among them are LubeWatch Premium, a comprehensive range of tests are run that are ideal for equipment under warranty and that meets OEM requirements for maintenance and UOA. ASTM standard is used along with Used Oil Analysis (UOA) service.

Meanwhile Lubewatch Lite provides fast turnaround, low cost, distributor, customer or end user managed non-ASTM UOA. It is ideal for operations who don’t use UOA for maintenance due to perceived cost issues and businesses that need a fast turnaround.

Lubewatch Now, on the other hand, is Caltex’s ultra-fast, low cost onsite managed non-ASTM UOA. With this service, you get instant results, and it is meant for real time trouble shooting and advisory.

To conclude, Caltex’s full gamut of products and services with in-house segment experts prove Caltex lubricant’s strength in maximizing power generation efficiency.