The role of gas engine lubricants in power generation applications

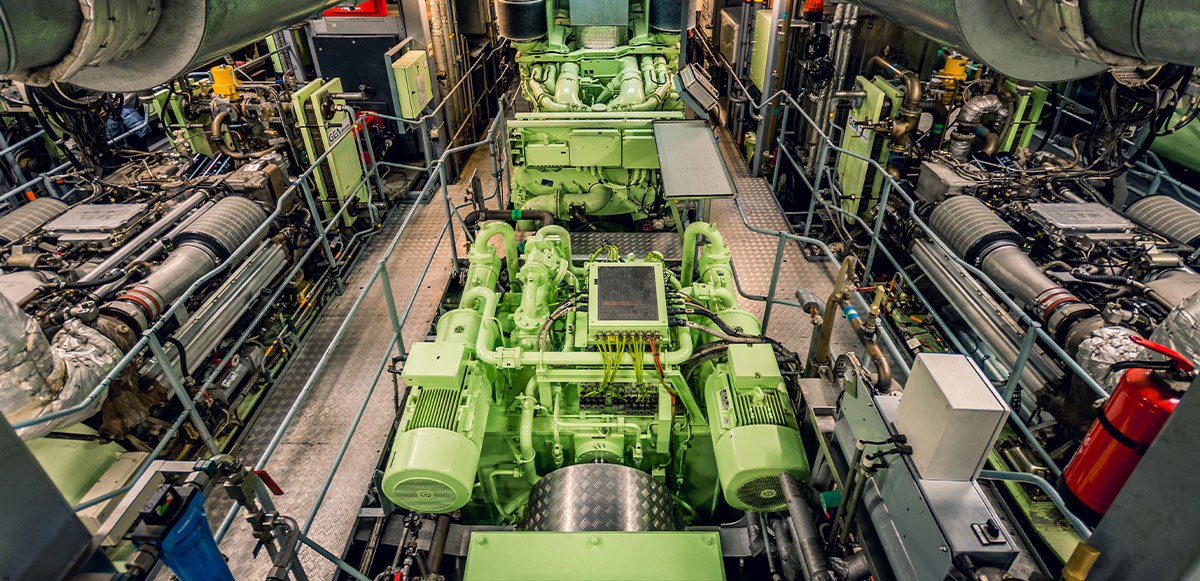

Efficiency and a profitable and healthier bottom-line is what plant maintenance operators handling Gas Engines, Co-Generation systems, Wind Turbines, Gas & Steam Turbines or Temporary & Back-up Power Generation Systems always strive towards. In doing so, lubricants play one of the most critical roles to reduce downtime, maximize drain intervals, ensure optimum performance and minimize losses.

Natural Gas Engine lubricants have critical functions to perform such as providing long oil life to minimize engine downtime and a safety margin when operating constraints require postponing routine maintenance. These lubricants can minimize high temperature deposits from forming on components, on the top deck and in the crankcase while inhibiting corrosion. Other required lubricant properties include oxidation and nitration resistance to provide long oil life; detergency to minimize harmful deposits from forming on piston crowns and ring grooves; dispersancy to minimize sludge particles from accumulating on top decks; and alkaline additives neutralizing acids increasing the potential for long oil service intervals.

Selecting a high-quality gas engine lubricant for power generation application becomes important, not only to optimize plant efficiency and uptime but also to prolong the life of the machines. Whether you’re providing base load or supplementing peak demand, your equipment must be running or be ready to always run, and this is where HDAX 7200 is sure to stand out.

Understanding HDAX 7200

This premium performance, long-drain, heavy-duty, low ash crankcase oil is specifically designed to lubricate a wide range of four-stroke natural gas and dual-fuel engines where low ash oils are recommended. This top-quality lubricant is formulated with hydrocracked base oils and additive technology to provide exceptional oxidation and nitration resistance, extended oil and filter life, outstanding protection against ring and liner scuffing and wear, and excellent piston and ring belt deposit control to effectively protect against the formation and build-up of engine sludge.

Applications Where HDAX 7200 can make a difference

HDAX 7200 works well in lean-burn and stoichiometric four-cycle stationary spark ignition engines burning sweet natural gas or LPG, operating under high load, high temperature conditions. This heavy-duty lubricant can be used in four-cycle medium-speed stationary spark ignition engines operating on sweet natural gas or LPG. Another effective application for HDAX 7200 is Four-cycle medium-speed stationary dual-fuel pilot injection engines operating on sweet natural gas or LPG. Additionally, this premium quality gas engine lubricant is formulated to meet NSCR catalyst compatibility requirements and is suited for installation requiring low phosphorus oil to help prevent exhaust catalyst poisoning.

The many benefits HDAX 7200 offers

Engine Performance Par ExcellenceHDAX 7200’s optimized detergent-dispersant additive package helps minimize the formation of engine deposits.

Valve Recession ProtectionThe level and type of ash-producing additives in the oil offers minimum valve recession with low levels of combustion chamber deposits to reduce the potential for pre-ignition and spark plug fouling.

Low Wear and TearHDAX 7200 also offers outstanding protection against piston, ring and liner scuffing, scoring and wear.

Valve Recession ProtectionThe level and type of ash-producing additives in the oil offers minimum valve recession with low levels of combustion chamber deposits to reduce the potential for pre-ignition and spark plug fouling.

Low Wear and TearHDAX 7200 also offers outstanding protection against piston, ring and liner scuffing, scoring and wear.

Extended Oil Life Its improved oxidation and nitration resistance delivers maximum flexibility in maintenance scheduling.

Squeaky Clean Pistons HDAX 7200 works to keep pistons clean, which helps prevent ring sticking and maintains clean, varnish-free piston skirts.

To know more about HDAX 7200, click here.