How switching to a clean oil can restore hydraulic pressure efficiency

When we talk to our industrial clients about the importance of oil cleanliness in improving equipment performance and extending its life, we sometimes hear the question: “If my equipment is already damaged, what is the point of putting clean oil in it?”

The answer may surprise you.

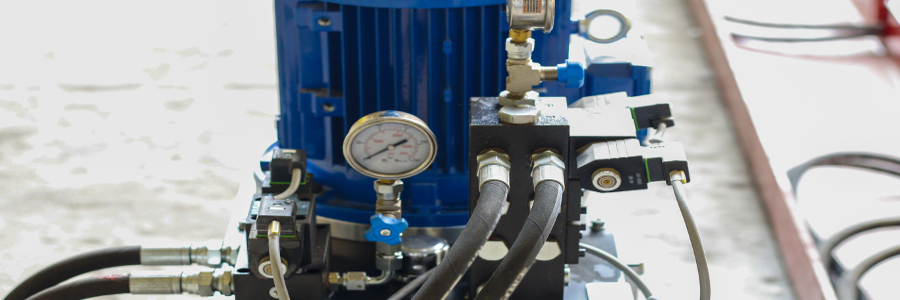

In a previous post, we looked at the impact of oil cleanliness on the pressure efficiency of hydraulic systems. Specifically, we shared test results showing how a typical hydraulic fluid that is not certified to the equipment manufacturer’s ISO cleanliness standards can have a jarring effect on system pressure and overall system performance. Using a certified clean hydraulic fluid, however, can result in smoother pressure and efficient performance.

But can switching to a clean oil restore hydraulic pressure efficiency?

The test:

In the course of our testing, we took apart a high-pressure Eaton vane pump to examine the relative wear caused by typical contaminated hydraulic fluids when compared to a clean hydraulic fluid.

We then put back together a pump that had experienced significant wear from a typical hydraulic fluid over a period of 150 hours and refilled it with a clean hydraulic fluid.

The results:

The results were fairly dramatic.

In the case of the typical hydraulic fluid, the pressure control valve had exhibited instability, as shown by a somewhat shaky pressure control curve. With the clean hydraulic fluid, the exact same valve exhibited a smoother pressure control curve.

Conclusion:

What this actually means is that you can stabilize a hydraulic system’s fluid pressure and gain operating efficiency by putting a certified clean oil even into a previously damaged system.

Whether you’re operating an excavator in a construction site or a plastic-injecting moulding machine, you can get a much more efficient performance, higher production and improved quality by changing out a typical hydraulic fluid for a certified clean lubricant. You may even get many more hours of useful life out of the equipment that would have otherwise been cut short by sticking with a typical contaminated hydraulic fluid.

Our advice is, of course, to always “start clean”. Our testing found a clear correlation between initial hydraulic fluid cleanliness and the amount of wear on hydraulic system components. We further concluded that fluid contamination can have a negative impact on system fluid pressure and efficiency.