Top 5 Signs You Are Using the Wrong Grease — And How to Fix It

Using the wrong grease can lead to equipment failures, unexpected downtime, and increased maintenance costs. Recognizing the warning signs early allows you to act promptly. Here are the top five signs your grease may not be right—and what to do about it.

1. Unusual Noise or Vibration

Why it Happens: The grease may lack the necessary load-bearing or lubrication properties for your equipment.

How to Fix It: Match the grease’s film strength, viscosity, NLGI grade, and EP (extreme pressure) additives to your application’s demands.

2. Overheating Components

Why it Happens: The grease might be breaking down at high temperature or failing to dissipate heat—leading to friction and heat buildup.

How to Fix It: Switch to a grease rated for high temperature or synthetic-based types with adequate thermal stability.

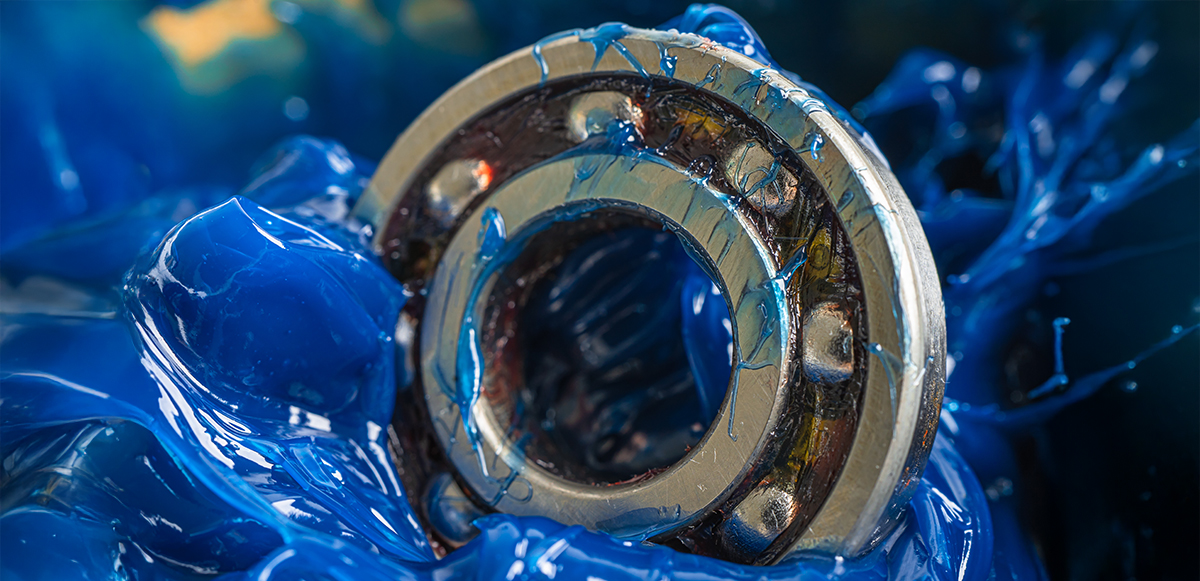

3. Premature Wear or Damage

Why it Happens: The grease might have poor anti-wear characteristics, insufficient protective additives, or be too light for the load.

How to Fix It: Use a heavy-duty or EP-formulated grease with proper viscosity, high film strength, and suitable additives like zinc or molybdenum.

4. Indicators from the Grease Itself

These are clear indicators that the grease is no longer appropriate.

Oil Bleeding Out

Why: Thickener breakdown or instability causes base oil separation.

How to Fix It: Choose grease with more robust thickeners (e.g., lithium complex, calcium-sulfonate) to improve stability.

Grease Too Thick to Pump

Why: Excessive stiffness or viscosity blocks flow in centralized systems.

How to Fix It: Choose for lower NLGI grade (0–1) or lower-viscosity base oil for better pumpability.

Dispensing or Flow Issues (Air Pockets, Poor Flow)

Why: Cold storage or improper packaging creates airlocks and uneven dispensing.

How to Fix It: Use cartridges with notched seals and follower plates to minimize air entrainment and waste.

Grease Breaks Down or Runs Out Prematurely

Why: Thermal degradation, contamination, or shearing compromises grease structure.

How to Fix It: Improve contamination control, reduce operating temperature, or switch to higher-viscosity or more stable formulations.

Premature Bearing Wear Despite Greasing

Why: Improper additive package or viscosity fails to protect against wear.

How to Fix It: Investigate mechanical alignment and load, then use grease with EP additives and correct base oil viscosity.

Grease Washing Out with Water

Why: Inadequate water resistance in the grease.

How to Fix It: Use water-resistant formulations like calcium-sulfonate, aluminum-complex, or marine-grade greases.

Grease Turns Dark or Black

Why: Oxidation, contamination, overheating—or even electrical arcing.

How to Fix It: Perform inspection for contamination or electrical issues, and possibly send grease for lab analysis.

Grease Turns Milky

Why: Water has contaminated the grease.

How to Fix It: Improve sealing to prevent ingress and select greases with better water-shedding characteristics.

Bearings Overheat After Greasing

Why: Over-greasing creates excess friction and heat.

How to Fix It: Apply grease sparingly—only as per recommended quantity—and purge excess.

Oil Pools in Stored Grease

Why: Excessive oil separation during storage.

How to Fix It: Stir minor bleeding back in before use; replace grease if separation is extensive.

5. Frequent Relubrication Needed

Why it Happens: The grease may be degrading too quickly or lacks enough structural stability for the operating conditions.

How to Fix It: Go for stable, long-lasting or synthetic greases designed for your specific workload; adjust intervals based on condition monitoring.

Final Thoughts

By carefully noting both performance-related signs and grease-specific indicators, you can catch mismatches before they harm equipment. Always align grease choice with operational requirements, consider environmental factors, and use proper storage and application techniques.