The new approach to varnish testing

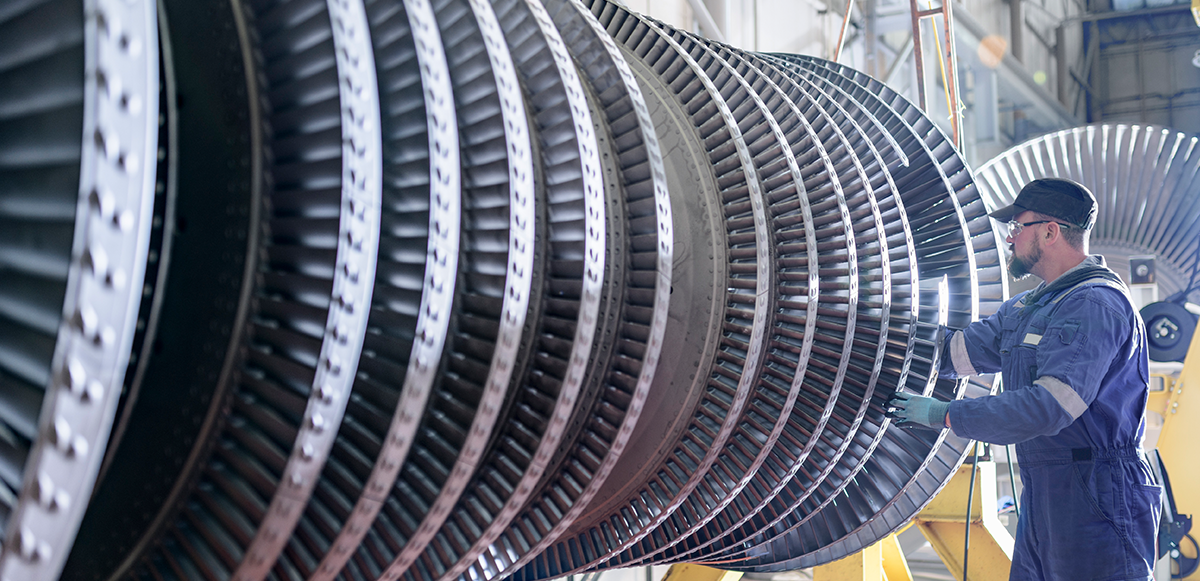

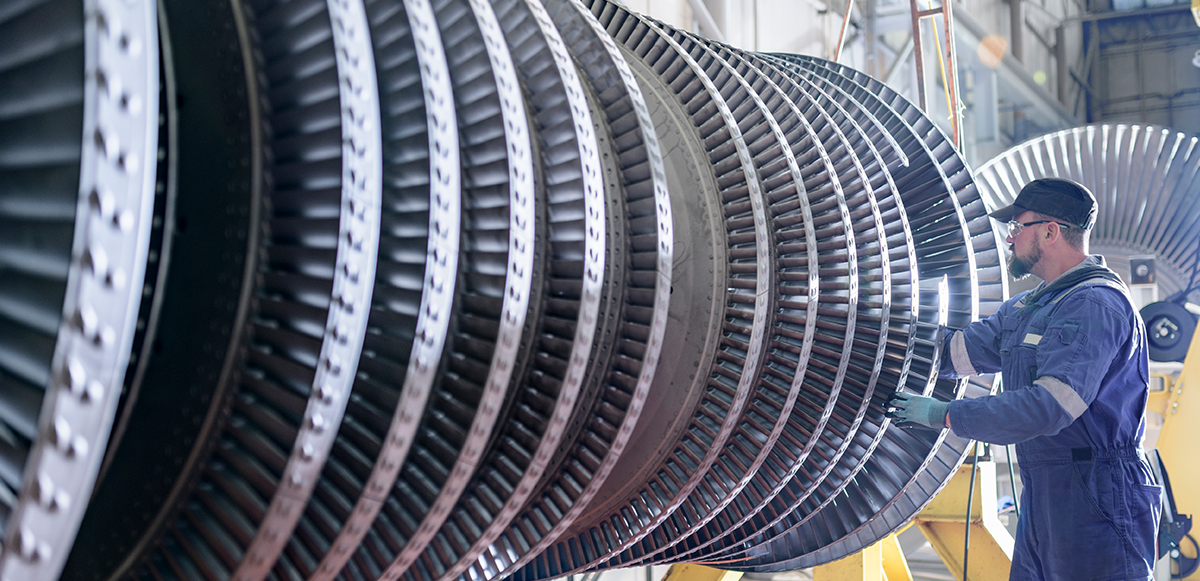

Varnish is a major problem, one that can hamper equipment performance, and sometimes result in expensive damage, if left unrestricted. One of the main issues with varnish is that you may not know if varnish has formed in a system until you start experiencing issues like sticking valves, blocked filters, etc. And varnish comes with a set of challenges; among them is trying to measure varnish resulting from oil degradation in turbines, compressors, and hydraulic systems.

As varnish forms on metal surfaces, it’s nearly impossible to gauge varnish itself; the only option is to take the equipment apart. This is why there has been a lot of focus on measuring varnish deposits or precursors in the oil.

Under the ASTM D7843 standard, the current standard for varnish measurement is the Membrane Patch Colorimetry, or MPC, test. In this test, a sample of in-service oil is passed through a very fine membrane patch devised to capture insoluble contaminants. According to the MPC test, any polar substances (attracted to metal), sticky, or larger than around 0.4 or 0.5 microns will cling to the patch and give it the color, which is then analyzed by a spectrophotometer. The color relays the extent of varnish precursors that are present in the oil. It means the darker the color, the higher the varnish potential.

In short, using the MPC test, an experienced lubricant analyst can infer from the data whether you have or will soon have varnish in the system.

Today, Chevron has teamed up with Polaris Laboratories, one of our independent LubeWatch® Oil Analysis Program partners, to develop a testing method that goes beyond the MPC and ASTM standard. The main objective is to give lubrication and maintenance engineers deeper insight into the root causes of varnish. This test relies not only on the color analysis of the patch, but also on changes to the weight of the patch, and how the accumulated substances respond to a polar solvent. For lab analysts, this can help distinguish between organic varnish precursors and insoluble hard particles, or inorganic compounds that may or may not add to varnish. This will help provide more detailed information about the types of varnish that may be present in your system, giving greater confidence in the test results and thereby to make a better-informed decision on remediation measures.