10 Reasons Why Meropa Lubricants Are the Ultimate Solution for Your Equipment!

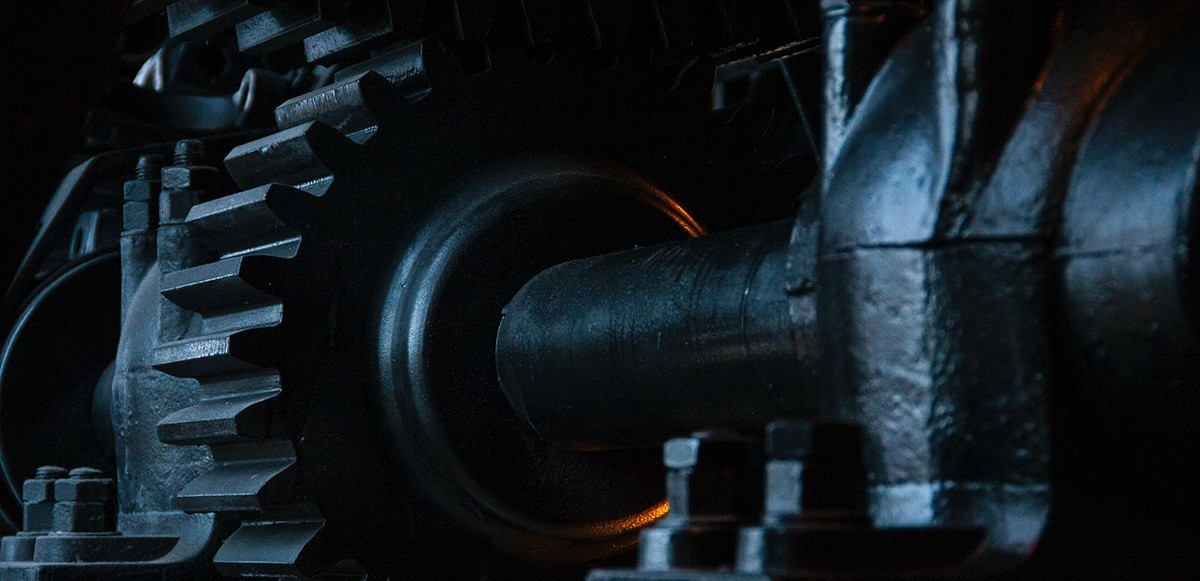

In the fast-paced world of industry, efficiency is key. Your equipment plays a crucial role in achieving this goal, and choosing the right lubricants becomes paramount.

Here are ten reasons why Meropa lubricants are designed to meet the demands of modern industry, providing superior performance and protection for your equipment.

Industrial gear lubricant, in particular, plays a crucial role in protecting gears and other moving parts from friction and wear, reducing downtime, and extending the life of your equipment. Industrial gear oils have to meet the following requirements, among others: excellent resistance to aging and oxidation; low foaming tendency; good load carrying capacity; non-corrosiveness towards ferrous and non-ferrous metals; neutrality towards materials used in gear casing (such as seals and paints); and good viscosity-temperature behavior. The natural or synthetic fatty additive combination in compounded gear oils results in good lubricity, providing additional protection measures to protect from metal-to-metal contact. Keep reading to find out why Meropa Lubricants are the ultimate solution for your equipment:

- Meropa lubricants are also used for the lubrication of a wide array of industrial and mobile equipment. Among typical applications are enclosed gear systems, chain drives, sprockets, plain and anti-friction bearings, slide guides, and flexible couplings.

- These lubricants are particularly suggested for enclosed gear drives and speed reducers, ranging from fractional kilowatt gear motors to large, high-power units on metal rolling mills, cement mills, and mine hoists.

- They are also suitable for the lubrication of industrial hypoid-type gears and are also recommended for use in transmission gear cases and worm drive axles on construction, and mining equipment.

- These lubricants are also apt for bath, splash, and circulation applications.

- Meropa lubricants also come highly recommended for mist systems used in a wide variety of fields such as steel, aluminum, chemical and paper equipment lubrication, and machine tools and materials handling equipment industries.

- Other specific applications for Meropa are in marine gearings, such as main propulsion, centrifuges, and deck machinery, including winches, windlasses, cranes, turning gears, pumps, elevators, and rudder carriers.

- Besides its many varied applications, Meropa lubricants have extreme pressure additives that optimize lubrication and minimize component wear.

- Its oxidation and thermal stability also protect at high temperatures, extending the oil's lifetime.

- Meropa lubricants’ corrosion and rust resistance also reduces maintenance and improves equipment uptime.

- Its superior demulsibility also ensures rapid water separation.