Understanding Diesel Engine Oil: API Specifications Explained

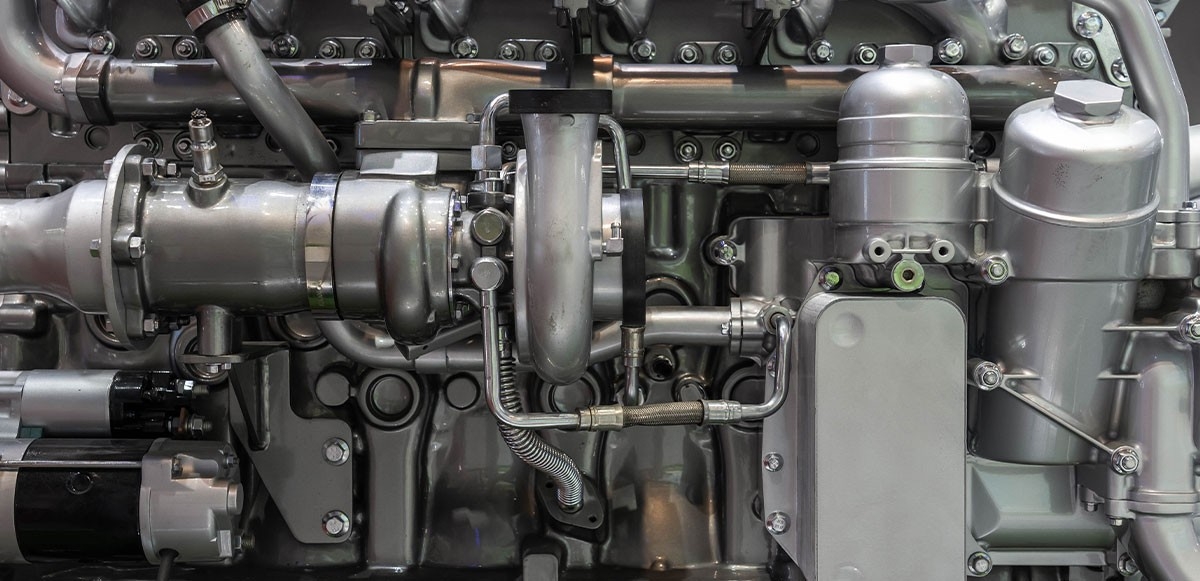

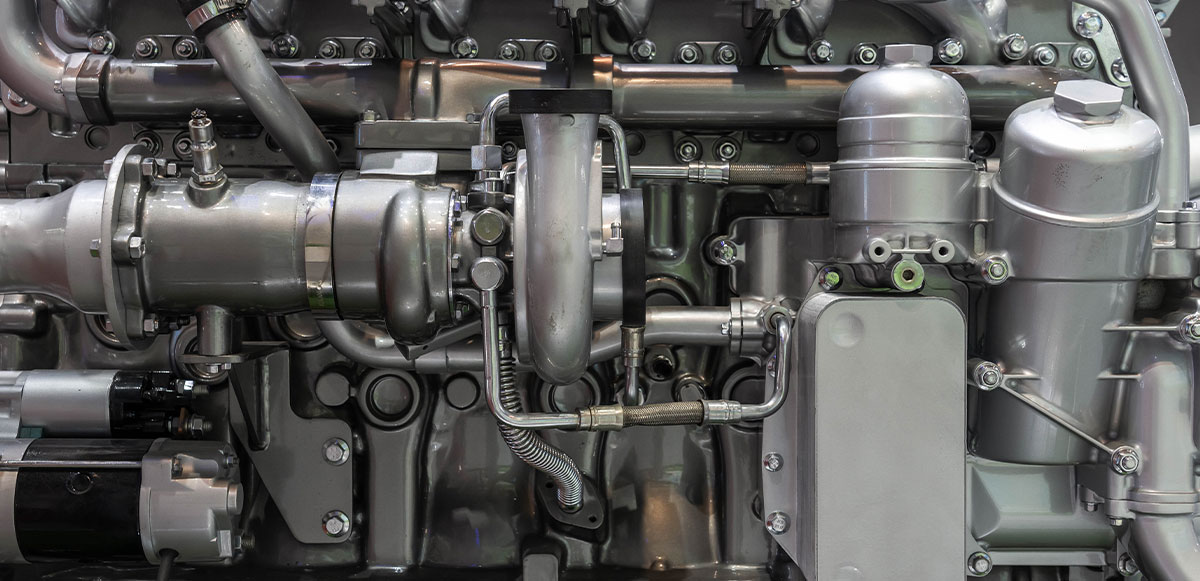

In the world of diesel engines, ensuring proper correct lubrication is paramount for longevity and optimal performance of diesel engines. Managing fleets of either singular or mixed diesel-powered workhorses is no small feat. Fleet owners rely on these engines to keep their operations running smoothly, delivering results, and ultimately, driving business forward. Proper maintenance is key to achieving this, and engine oil sits at the heart of it all.

But with a vast selection of engine oils available, choosing the right one can be a challenge. This is where API categories come in. Even if you're an experienced fleet owner, or perhaps you're new to the world of diesel engines, understanding these classifications is crucial for selecting the optimal oil and maximizing the performance and lifespan of your fleet.

API categories explained: API categories for diesel engine oils follow a simple two-letter format, like CF-4 or CI-4. Here's what each part signifies:

First Letter (C): This denotes the oil's suitability for diesel engines (indicated by "C").

Second Letter: This represents the oil's performance level, with higher letters indicating better performance for modern engines.

API CH-4: API Service Category CH-4 describes oils for high-speed four-stroke cycle diesel engines designed to meet 1998 exhaust emissions standards and for previous model years. CH-4 oils are specifically compounded for use with diesel fuels ranging in sulfur content up to 0.5% weight. These oils are especially effective to sustain engine durability even under adverse applications that may stress wear control, high-temperature stability, and soot handling properties. In addition, optimum protection is provided against non-ferrous corrosion, oxidative and insoluble thickening, foaming, and viscosity loss due to shear. These oils also have the performance capability to afford a more flexible approach to oil drain intervals in accordance with the recommendations of the individual engine builders for their specific engines.

API CI-4:API Service Category CI-4 describes oils for use in high-speed four-stroke cycle diesel engines designed to meet 2004 exhaust emission standards implemented in 2002. These oils are intended for use in all applications with diesel fuels ranging in sulfur content up to 0.5% weight. These oils are specifically formulated to sustain engine durability where Exhaust Gas Recirculation (EGR) is used and the impact of these oils on other supplemental exhaust emission devices has not been determined. Optimum protection is provided against corrosive and soot-related wear tendencies, piston deposits, degradation of low- and high-temperature viscometric properties due to soot accumulation, oxidative thickening, loss of oil consumption control, foaming, degradation of seal materials, and viscosity loss due to shear.

API CJ-4:API Service Category CJ-4 describes oils for use in high-speed four-stroke cycle diesel engines designed to meet 2010 model year on-highway and Tier 4 nonroad exhaust emission standards as well as for previous model year diesel engines. These oils are formulated for use in all applications with diesel fuels ranging in sulfur content up to 500 ppm (0.05% by weight). However, the use of these oils with greater than 15 ppm (0.0015% by weight) sulfur fuel may impact exhaust aftertreatment system durability and/or oil drain interval. These oils are especially effective at sustaining emission control system durability where particulate filters and other advanced aftertreatment systems are used. Optimum protection is provided for control of catalyst poisoning, particulate filter blocking, engine wear, piston deposits, low- and high-temperature stability, soot handling properties, oxidative thickening, foaming, and viscosity loss due to shear.

API CK-4:

API Service Category CK-4 (see Annex I, Table I-4) describes oils for use in high-speed four-stroke cycle diesel engines designed to meet 2017 model year on-highway and Tier 4 non-road exhaust emission standards as well as for previous model year diesel engines. These oils are formulated for use in all applications with diesel fuels ranging in sulfur content up to 500 ppm (0.05% by weight). However, the use of these oils with greater than 15 ppm (0.0015% by weight) sulfur fuel may impact exhaust aftertreatment system durability and/or oil drain interval. These oils are especially effective at sustaining emission control system durability where particulate filters and other advanced aftertreatment systems are used. API CK-4 oils are designed to provide enhanced protection against oil oxidation, viscosity loss due to shear, and oil aeration as well as protection against catalyst poisoning, particulate filter blocking, engine wear, piston deposits, degradation of low- and high-temperature properties, and soot-related viscosity increase.

Choosing the right API specification for diesel engine oil depends on various factors, including the engine's age, design, operating conditions, and emission control systems. It's essential to consult the vehicle manufacturer's recommendations and consider the API service category to ensure optimal engine performance and longevity.

In conclusion, understanding the API specifications for diesel engine oil is crucial for business owners especially to maintain the health and efficiency of their diesel engine investment, maximizing uptime and ensuring long-term profitability. Whether it's an older model or a state-of-the-art vehicle, selecting the appropriate API service category ensures proper lubrication, reduces wear and tear, and contributes to a cleaner environment through improved emission control.

Caltex Delo advanced products including engine oils and lubricants are formulated to meet stringent API specifications, offering heavy diesel engine equipment peak protection while lowering maintenance costs. View the full range here.