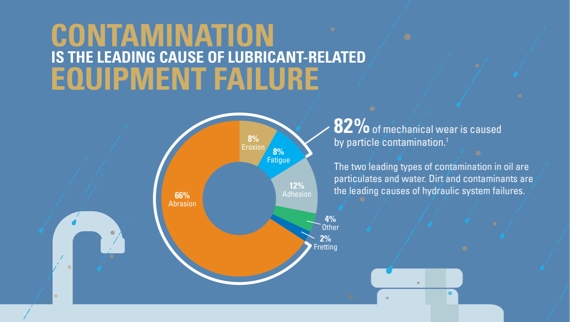

Oil particle contamination is the number one cause of

lubricant-related breakdowns. But the majority of typical new oil is not

certified to meet a specific ISO cleanliness level at the point of delivery—and if

the new oil you’re buying doesn’t even meet OEM cleanliness specifications at

the start, you’re adding more risk up front that will cost you more to fix when

your equipment fails later.

Take a deeper look at how particle contamination affects equipment life to understand the measurement of contamination levels in oil and how relying on equipment filters or trying to pre-filter new oil on site could be putting your equipment at risk.

Use our free, easy tool to estimate possible equipment damage by comparing your current oil cleanliness to the level required to maximize equipment component life.

Why system filters are not enough protection

The chain reaction that starts with particle contamination

is a scary process, and the impact can be felt far beyond just the parts and

labor costs. Here’s the quick version of how starting with clean oil can help

you begin to reduce contaminant-caused wear.